Manufacturing system

ISO9001 quality management system

Dingge Motor takes the quality management team as the core and strictly implements and organically combines the various documents of the ISO9001 quality management system. In the continuous development of the enterprise, it has formulated various process discipline documents that meet the requirements of high-reliability generator products. The standard is higher than the national standard and industry standard;

Dingge Motor has successfully operated the ERP management system, and realized the orderly and integrated management of procurement, production and inventory; adhered to the production concept of lean manufacturing, and effectively implemented the 6S on-site management process to achieve clean, orderly and high-quality production in large-scale production. Quality, efficiency, and elimination of waste, to ensure that the one-time pass rate of products meets the standard.

For example, using Dingge's own imported large-scale three-coordinate monitor as a practical means, the institutionalized supervision and inspection of each batch of raw materials entering the factory has been institutionalized and the posts and personnel are in place;

Manufacturing process and quality control points: DINGOL has set up a number of careful and rigorous manufacturing process processes. In order to achieve the management goals of different process processes and achieve a one-time pass rate of higher than 95% for the whole machine, DINGOL has set up the quality of multiple processes. Control points, different processes implement a rigorous assessment system, to achieve the quality standards of each process from passive detection to active control of employees in various positions.

Management and maintenance of equipment and tooling tools: DINGOL has formulated a management and maintenance system responsible for the modern hardware equipment and generator tooling tools to ensure that the equipment accuracy corresponding to the manufacture of different batches of products can be unified standards, and ensure that each batch of complete machine products can be produced. The quality of the products can be stable throughout the period; a complete equipment maintenance system has been established, so that the equipment wear parts can be regularly maintained and replaced, and the quality of the products in each process is guaranteed to be stable between batches. In addition, the top grid motor has formulated rules and regulations and personnel assessment systems that are higher than industry standards for product process inspection and factory inspection of complete machine products, and strictly implement them. The Dingge team looks forward to the majority of users coming to Dingge factory for on-site experience and on-site inspection.

PPM management mode to operate the manufacturing platform

The company implements unified process standards and technical specifications for the manufacturing system consisting of the first-phase base and the second-phase base, and sets a unified PPM target value for each process. Establish a complete and unified standard post responsibility system, and strictly implement and evaluate it; thus ensuring that the one-time pass rate of top-quality manufactured products is higher than 95%, and the product ex-factory pass rate is 100%. And to ensure that the quality of different batches of long-term supporting customer products is lasting and stable.

Based on the continuous maturity and improvement of the operating experience of the PPM management model, the DINGOL manufacturing system has won many global high-tech companies in order to solve the delivery ability of strategic partners' large-scale supporting product orders and the active control ability of high-quality lasting stability and zero fluctuation of quality between batches. Fully recognized by high-quality power station manufacturers, it has become the generator OEM supplier of many world-class power station brand enterprises.

Manufacturing equipment scientific application and maintenance:

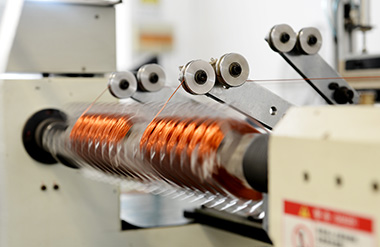

Hardware facilities that meet the requirements of various manufacturing processes for continuously running generators and conform to domestic and international generator industry specifications:

In the corporate culture of Dingge Motor, people-oriented is strengthened. The operator is the owner of the equipment, who can control it skillfully and take care of it carefully; strengthen the scientific application and maintenance system of the equipment, and provide the team leaders and equipment operators for each process. Establish regular equipment application training and safety education; at the same time, establish a sound equipment maintenance and maintenance system to ensure that various advanced manufacturing equipment can continue to function and ensure the lasting stability of product quality between batches;

Skilled application and system of many equipment including modern large-scale rotary heat soaker, fully enclosed painting line with drying function, modern large-scale three-dimensional storage platform, large-scale three-coordinate instrument for raw material incoming quality monitoring equipment, feedback generator test platform, etc. Regular maintenance is scheduled to ensure that the industry's advanced manufacturing equipment can continue to exert high-efficiency, high-precision, and high-stability application performance, and to ensure that the quality of generator supporting products is lasting and stable.

Procurement system

SCM (Supply Chain Management) System and Quality Improvement

DINGOL has built an independent, mature and large-scale generator manufacturing equipment and high-quality raw material procurement platform together with qualified sub-suppliers based on the principles of honesty and trustworthiness, win-win cooperation and common development. Ensure the long-term stability of the supply chain material quality and the timeliness of sufficient supply of high-quality raw materials to meet the delivery of bulk orders;

The platform implements a qualified supplier access process, requiring qualified sub-suppliers to establish a quality plan for top-quality components, and all components are under control.

Among them, the supply chain management system (SCM) strengthens the continuous improvement process of supplier product quality.

As the designated supporting enterprise for generators of high-quality power plant completers in the world, Dingge Motor has extensive and stable supporting orders from all over the world; customers around the world continue to demand and increase the development of emerging markets, which further promotes Dingge Motor and excellent supply chain partners. The continuous improvement and diligent pursuit of new product matching and R&D strength. Top grid motor's annual investment in research and development of new products is not less than 8% of the annual profit.

PPM management mode to operate exclusive procurement platform

DINGOL's independent raw material procurement system also adopts the PPM method to continuously improve 'evaluation, improvement, and verification' to ensure that the reliable quality of the exclusive generator parts of DINGOL's procurement system can meet the large-scale delivery of large orders and between different batches. Combined with the quality plan of qualified sub-suppliers, the DINGOL team and supply chain partners jointly build a continuous improvement process for raw material quality to ensure that the quality of raw materials meets the standard; it has become a necessary means for the one-time pass rate of the whole machine to be higher than 95%.

In order to realize the fairness and authority of the operation of the Dingge raw material procurement platform, Dingge Company introduced a large imported three-coordinate instrument, the equipment detection accuracy can be controlled within 0.01mm, and the access of machining raw materials is monitored; the raw material processing accuracy of Dingge Motor is generally excellent Compared with the same type of generator products, it can create good low noise effect and long-lasting precision for customers.